RCD's shall be fixed setting RCD's complying with AS/NZS 3190, AS/NZS 610081.1, AS/NZS 61009.1, or IEC 62423 and intended for use in electrical installations.

Why use RCD's?

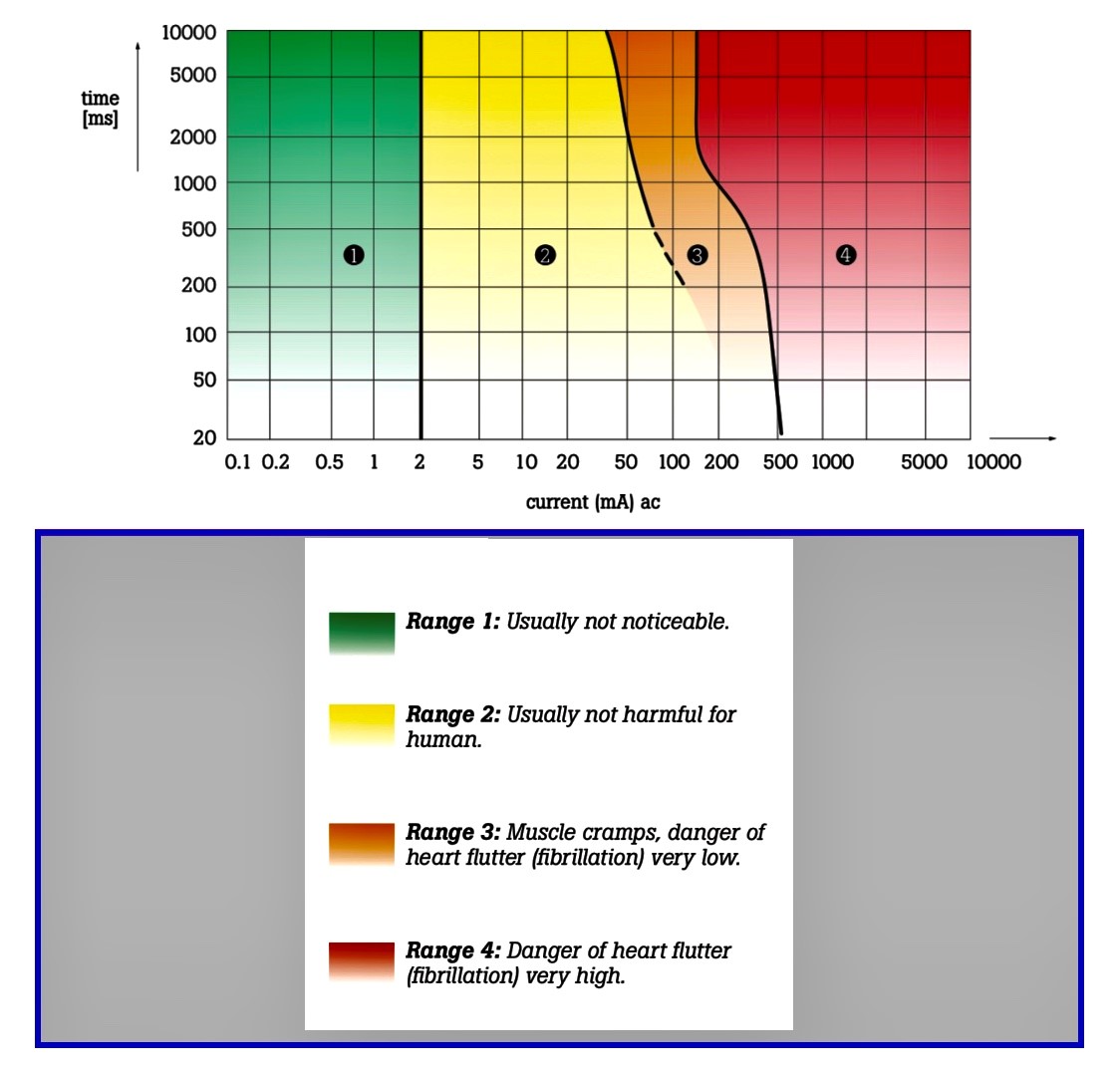

An RCD detects fault currents flowing to earth that are too small to trip over-current protection devices (such as circuit breakers or fuses), but are still sufficient to cause a dangerous electric shock (see also figure attached) or an electrical fire. Verifying their operation is critical for safety, and is covered in IEC 60364 (and its various national equivalent standards). This standard specifies the requirements for fixed electrical installations in buildings.

Why do we test RCD's?

Most RCD's have an integral test button, but even a successfully completed test using this facility does not necessarily confirm that the RCD is working correctly. Additional tests to measure tripping time are necessary to verify that the RCD will perform correctly under fault conditions, while extra tests may also be carried out to determine the actual tripping current. In standard regulations, testing RCD's fall under ‘Verifying protection by automatic supply disconnection’. Depending on the type of system, that is TN, TT or IT, various test procedures are used. These include measurement of the fault loop impedance, measurement of the earth-electrode resistance for exposed-conductive-parts of the installation, and measurement or calculation of the first fault current. In all these procedures, verifying the characteristics and operation of protective devices such as circuit breakers, fuses and RCD's is critical.